The production of gelatin is achieved by partially hydrolyzing the collagen in animal skin using acid, alkali, or enzymatic methods. The gelatin is then extracted by heating, filtered, concentrated, sterilized at high temperatures, dried, and crushed. Therefore, the gelatin production process involves transforming natural insoluble collagen into a water-soluble colloid,

1. Raw materials

Strictly control the standards for raw material entry into the factory, and select suppliers with production qualifications to use fresh animal skins as raw materials.

2. Handling

After washing the raw materials with water, the collagen in the raw materials is partially hydrolyzed using alkali or acid methods, causing the collagen to break and separate from the rod-shaped triple helix structure, preparing for subsequent heating and gel extraction.

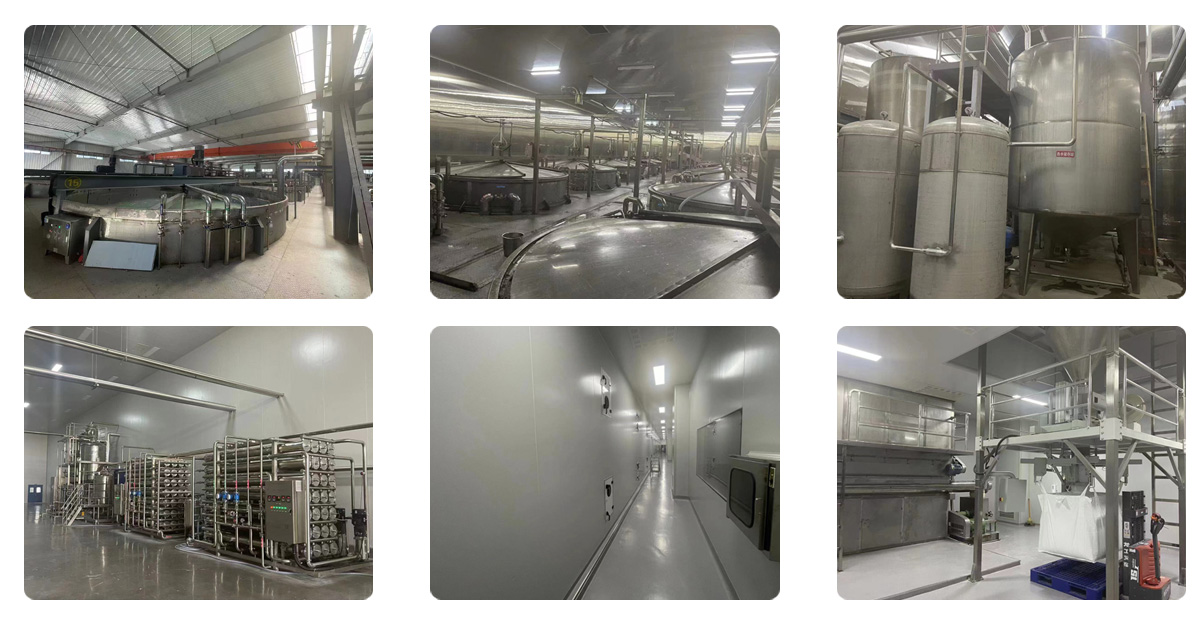

3. Glue lifting

After the raw materials enter the glue extraction pot, slowly heat them up to 55-65 ℃, soak them in hot water for 6-8 hours, and then release the glue solution; Add hot water to the pot again, increasing the water temperature by 5-10 ℃ compared to the previous time, and continue to extract the gel. Repeat this process multiple times, gradually increasing the temperature each time. Finally, boil slightly to allow the gel source in the skin tissue to completely dissolve into the water and form a gel solution.

4. Filtering

Use filter cotton, activated carbon, or diatomaceous earth as filter aids to filter the diluted gel obtained from the extraction process, and use a plate and frame filter press to remove solid impurities from the gel solution and obtain a clear gel solution.

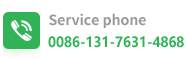

5. Concentrate

The clarified gel solution is passed through an ultrafiltration membrane filter and a flash evaporator to increase the concentration of the original gel solution from 4% -7% to 25% -30%.

6. Sterilization

The concentrated adhesive solution is sterilized instantly at a high temperature of 140 ℃ for 6 seconds using a U-shaped tube sterilizer, and then rapidly cooled to 55-60 ℃ before being sent to the equilibrium tank. Practice has proven that Escherichia coli and Salmonella can be effectively killed at this temperature and time,

7. Long net drying

After sterilization, the concentrated adhesive solution is cooled and extruded into long strips by an extruder, which are evenly laid on the mesh belt of a long mesh dryer. After passing through 8 drying chambers, the temperature is gradually increased to slowly remove the moisture in the adhesive strip. The strip is dried continuously for about 3 hours to obtain an adhesive strip with a moisture content of 9% -11%. After crushing, it enters the semi-finished product for hydrolysis

8. Finished product mixing

According to customer needs, semi-finished products with different indicators are blended to produce finished products that meet customer requirements,

9. Finished product testing and shipping

The quality control department conducts testing on the mixed finished products, and we have developed internal control standards for enterprises that are higher than national standards. All finished products that leave the factory are guaranteed to meet the highest standards and requirements at home and abroad.